Material Library

Beauty, durability and practicality.

Terrazzo is a staple in the design toolbox, seamlessly blending the timeless elegance of marble with the unmatched durability of cement. Its smooth, polished surface exudes sophistication and enhances spaces with striking depth and radiant luminosity. This unique combination makes this material an ideal choice for those seeking both style and practicality in flooring solutions. Available in a wide range of colours and aggregate options, terrazzo allows for customisation that suits any aesthetic preference. Whether opting for a bold statement or a subtle, neutral tone, designers can easily achieve their vision.

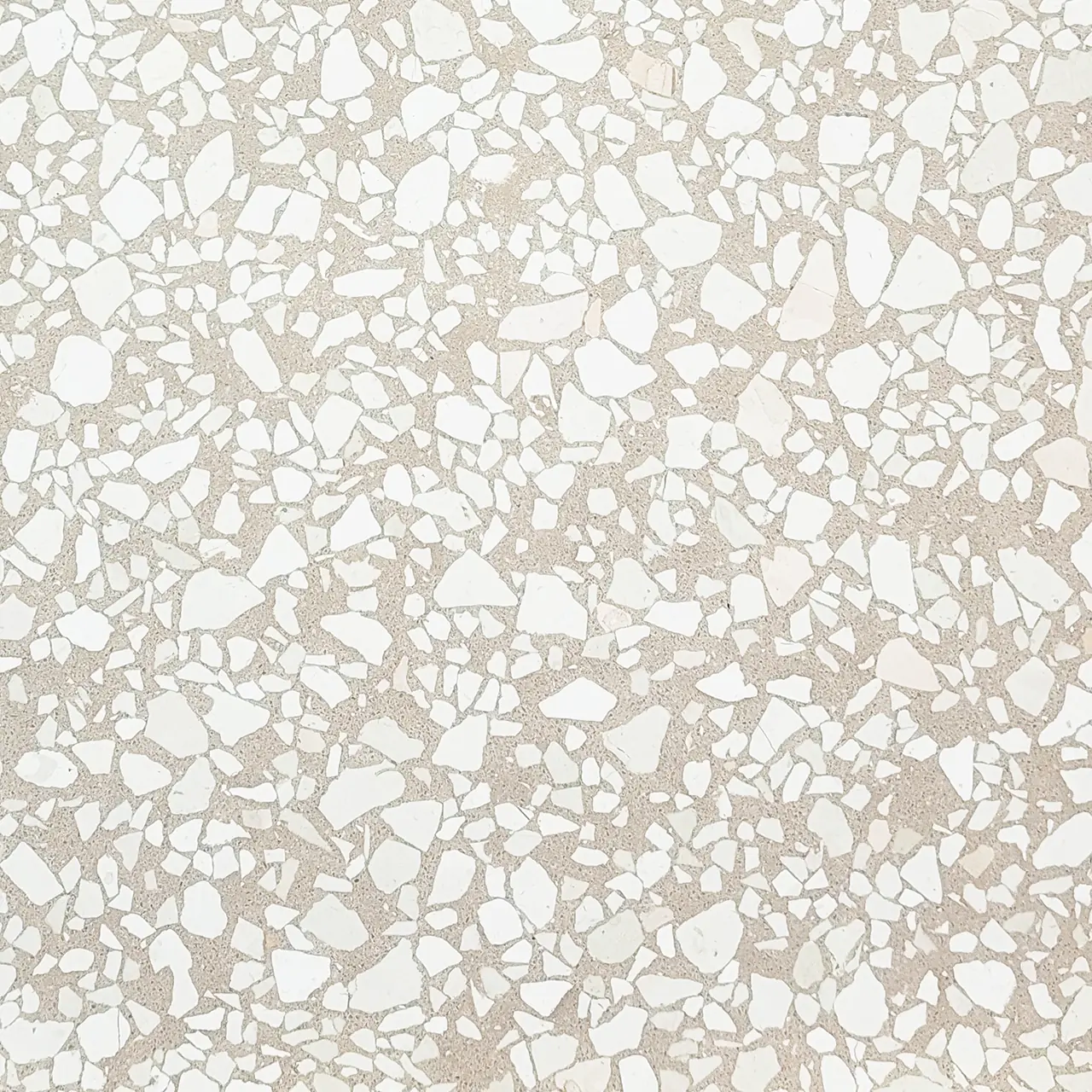

BIanco Inglese

Bianco Inglese reflects a dialogue between past and present, where timeless craft meets contemporary design

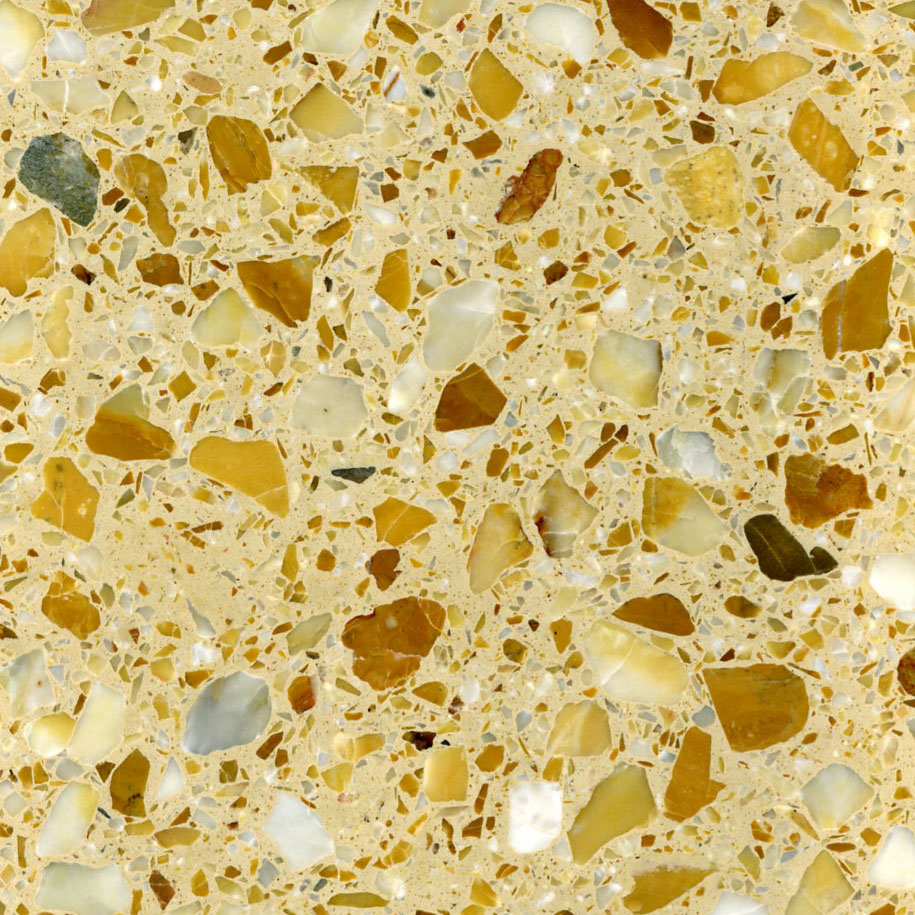

Giano Terrazzo

Giano terrazzo reflects a commitment to renewal, responsibility, and lasting value in a world demanding change.

Terracotta Terrazzo

Terracotta terrazzo blends sustainability with durability.

Classic Terrazzo

Classic terrazzo embodies timeless elegance and enduring charm.

Veneziana

Veneziana holds a special place as the oldest and one of the most stunning collections we offer.

Project

Project can transform spaces with a sleek, modern look while maintaining the distinctive character of this traditional material.

Matonnella

Mattonella stands out for its versatility and innovation featuring a diverse palette of colours.

Transitioning seamlessly between residential, commercial, and public spaces, terrazzo flooring enhances the ambiance of any setting.

Beyond its visual appeal, terrazzo flooring delivers unparalleled durability, making it a smart choice for high-traffic areas. It resists wear and tear, maintaining its beauty for years while requiring minimal upkeep. Additionally, the sustainable production process and use of recycled materials align with eco-friendly design goals.

Explore the texture options that can be applied to these materials. Our innovative surface treatments bring an added dimension to elevate your next project.